Product introduction:

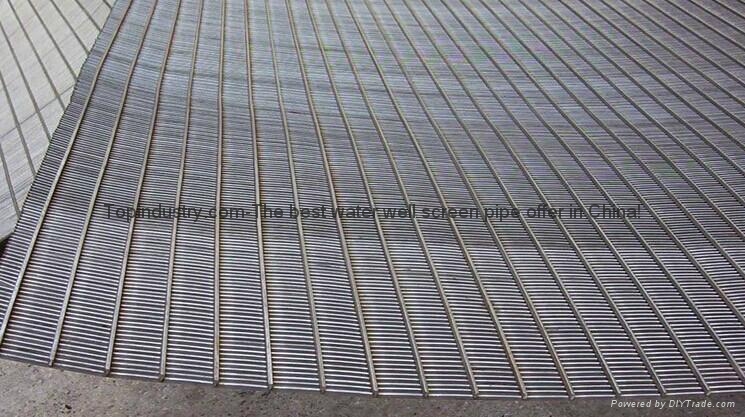

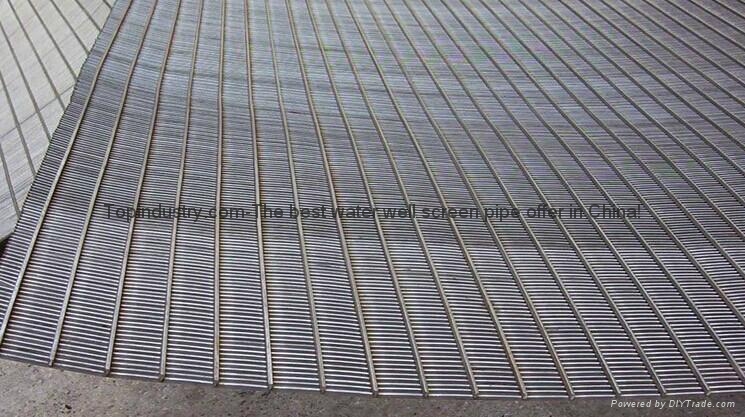

Sieve plates is a metal mesh structure used for screening filter element. Made from cold-rolled steel strip wire and support rod, using automated production equipment welded technology, the dimensions, wire diameter, slot and frame structure can be customized. Round,square, fan shaped are available.

Material:Low carbon steel wire, high-manganese steel wire, stainless steel wire SS304,304L, 316, 316L, 2205 austenitic stainless steel, Hastelloy, etc.

Feature:

1. Using special leveling device, smooth surface, no wavy bumps, homogeneours wear during use

2. With high opening rate, big filter area, fast filtering speed.

3. Special welding technology makes the joint solid, structure firmed, integrity is strong, even if some part is damanged or under pressure, slack phenomenon is not occured.

4. Good corrosion resistance and wear resistance.

5. Small maintenance workload. Reasonable high-strength seam sieve structure, not easy to damage, long service life, it can greatly reduce the maintenance and production losses.

6. Low using cost. Long service life greatly reduce the total cost of users.

7. The mesh design is reasonable, with V or T wire, aperture on narrow down the wide, the particle size limits will not block the screen hole, high screening efficiency.

8. Homogeneous sieve slot, smooth screen surface, strong sieve permeability, minimum gap precision can be up to 15 microns.

9. This product has advanced and superior production technology,the structure design is more perfect. Its service life is 1 times more than similar domestic products.

Application:

It is widely used in mining, coal plant screening, drilling, fertilizers, food, environmental protection, metallurgy, medicine and other industries, also used in liquid, powder materials filtering on acid, alkali environment conditions, oil industry as mud mesh, chemical fiber industry as screen mesh, electroplating industry as pickling nets, plastic industry (the sieve plate of EPS molding machine) and so on.